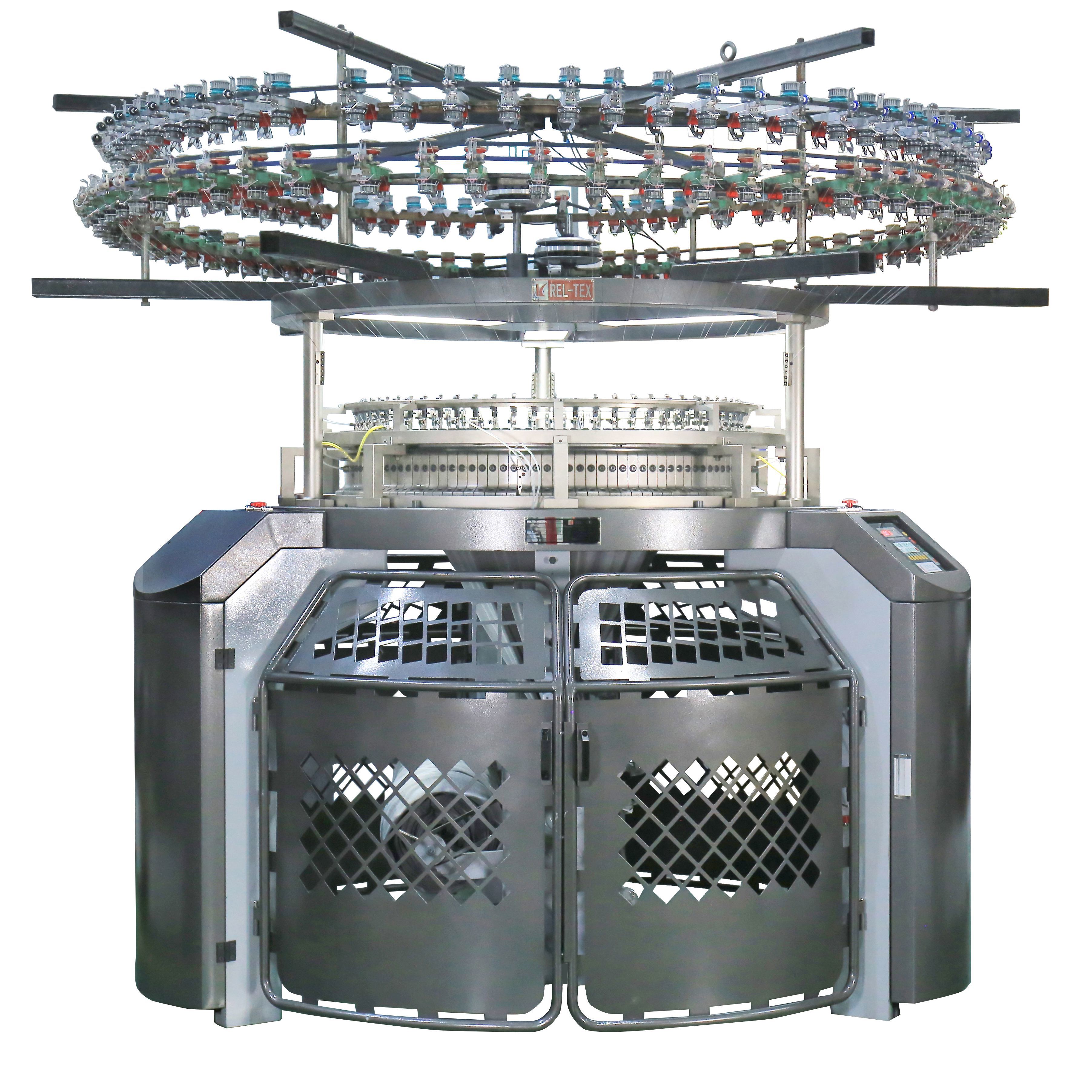

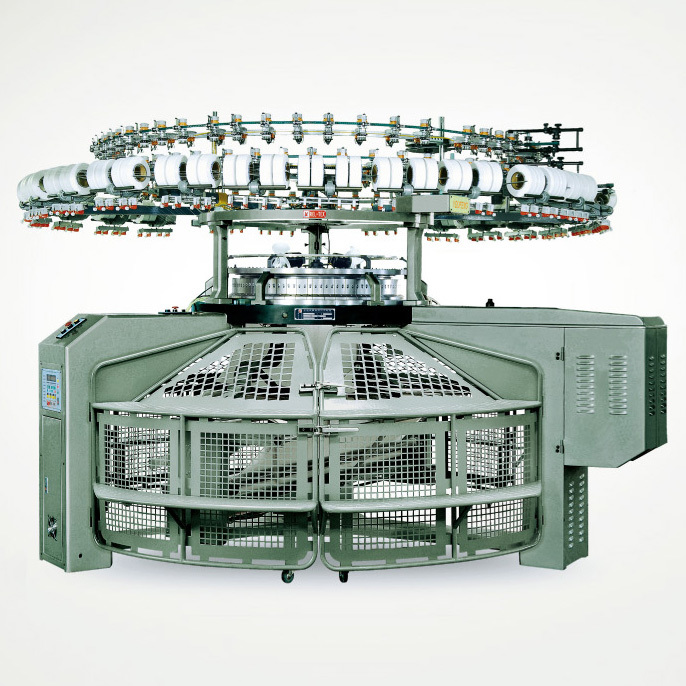

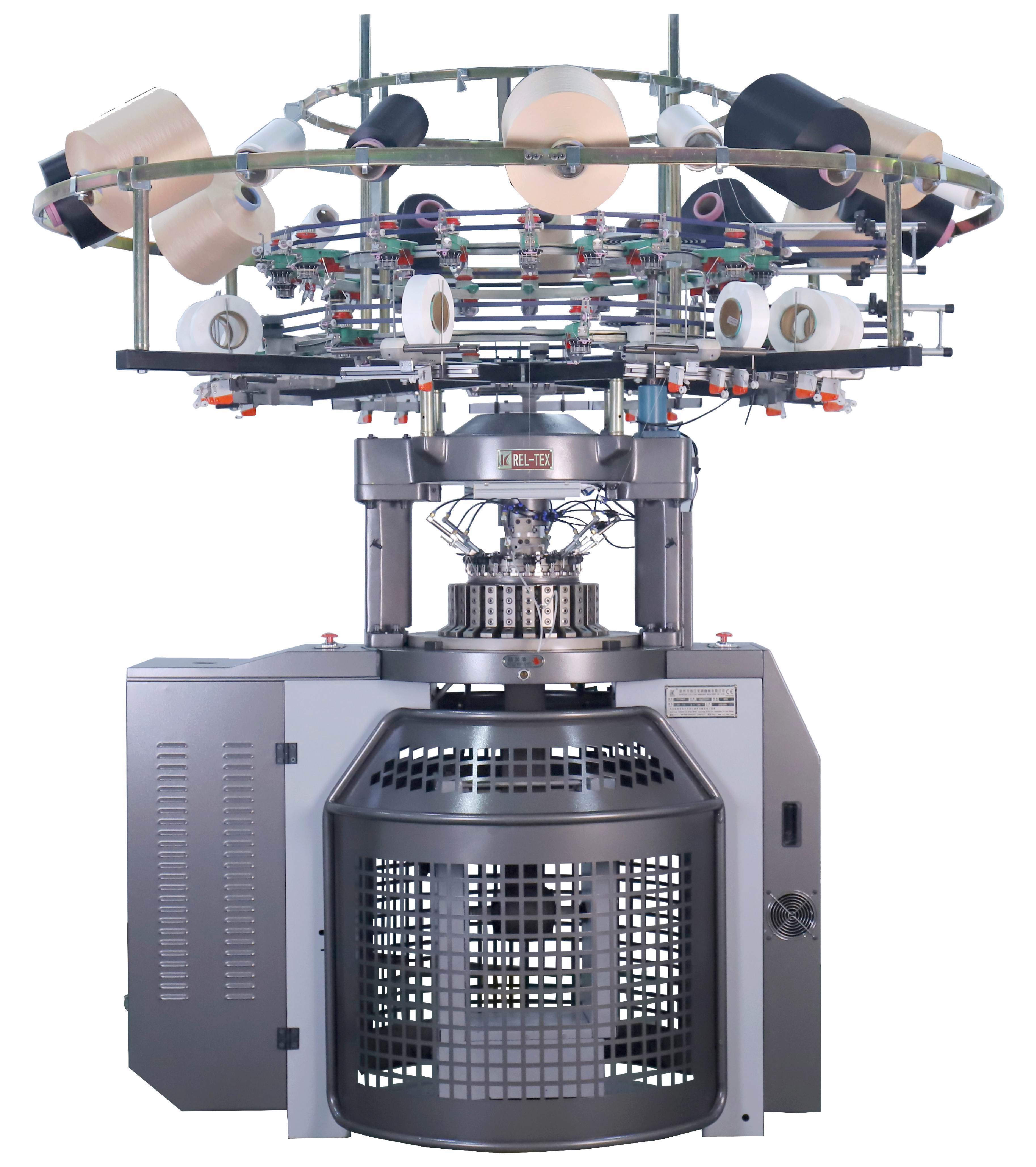

Single Jersey Circular Knitting Machine

Machine model:

YFSG

Classification:

Product Description

Single Jersey textiles always dominate the major trend in knitting industry. In order to meet these tremendous needs, REL-TEX High Speed 4 Track Single Jersey Circular Knitting Machines are able to knit plain and pique design fabrics etc easily by arranging the 4 track cylinder cams- knit, tuck, and miss for many different kinds of patterns.

Machine Function:

REL-TEX brand had introduced YFSG models with InterChangeable Conversion Kit and thereby facilitates the multi-function single jersey knitting tasks – Terry, Velour, Three-Thread Fleece - apply to REL-TEX versatile single jersey knitting machine.

■ Oil-Bathed Structure: The Oil-based frame prevents Gear Ring from rusting and further smoothes the performance of rotation.

■ Concatenated Sinker Cam: New design of the doubled sinker-track guidances prolongs the service life of sinker. It will reduce friction between the sinker and the sinker cam, and avoid the defective lines on the fabric.

■ Yarn Carrier: Tailor-made vertical yarn guide wheels prevent the needle from damage while applying Lycra/ Spandex and reduce the accumulation of extra cotton fiber.

■ Cloth rolling system is a special design, which easily rolls up the cloth and will not produce clear shadow. In addition, the machine is equipped with a safety stop device that will shut down the entire machine automatically once the problem occurs.

■ Central Stitch Adjustment: Can be equipped on machine to adjust the fabric density and gram weight rapidly and precisely.

■ Lycra feeding unit can be installed on the machine to produce high quality elastic fabrics.

Fabrics Application:

The needles and cams can be arranged to produce a variety of patterns and thickness of fabrics. The knitted fabrics including single jersey plain fabrics, single jersey pique fabrics, twill, meshed fabrics, 2 thread fleece etc.

Machine Specification:

| Model | Cylinder Dia. | Gauge | Feeder |

|---|---|---|---|

| YFSG | 12”~50” | 6G~40G | 3F/INCH |

| YFSG | 12”~50” | 6G~40G | 4F/INCH |

| YFSG | 12”~50” | 6G~40G | 6F/INCH |

Our plant is equipped with a lot of advanced production equipment, such as the CNC vertical lathe, high-speed milling machines, CNC machining center and so on. There devices are imported from Japan & Germany and we gradually expand our plant, now our annual output can reach more than 2000 sets, before the shipment , machines will be adjusted and inspected by our technicians, so as to make sure that all machines are qualified.

Related products