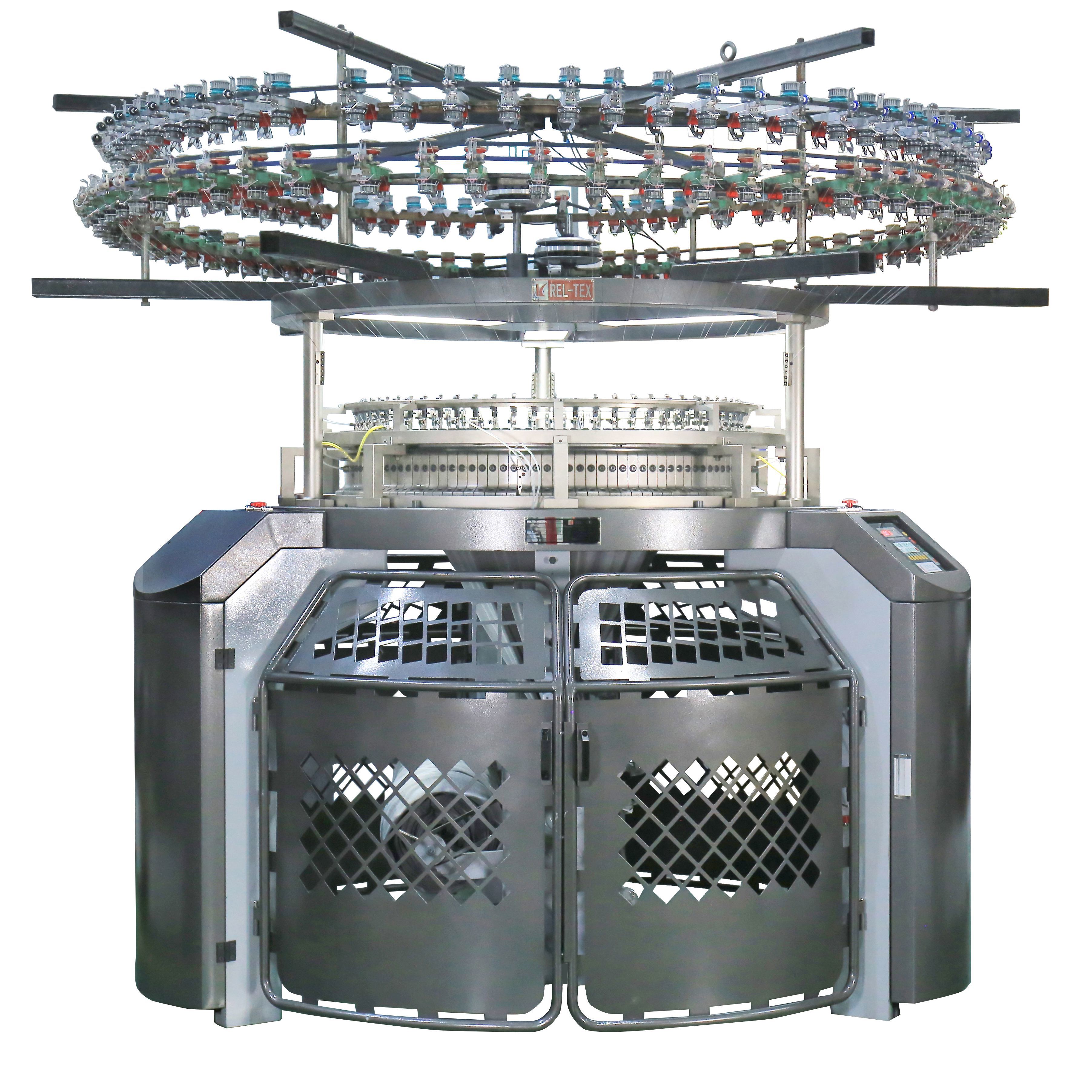

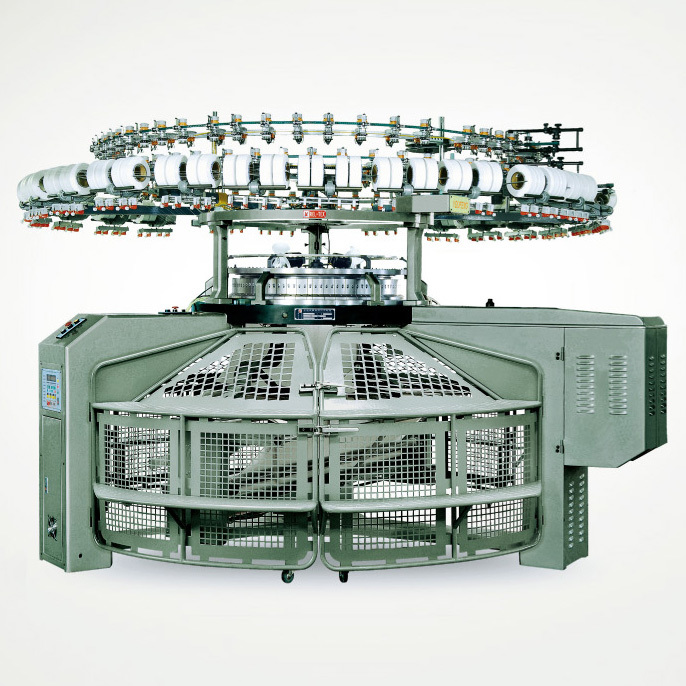

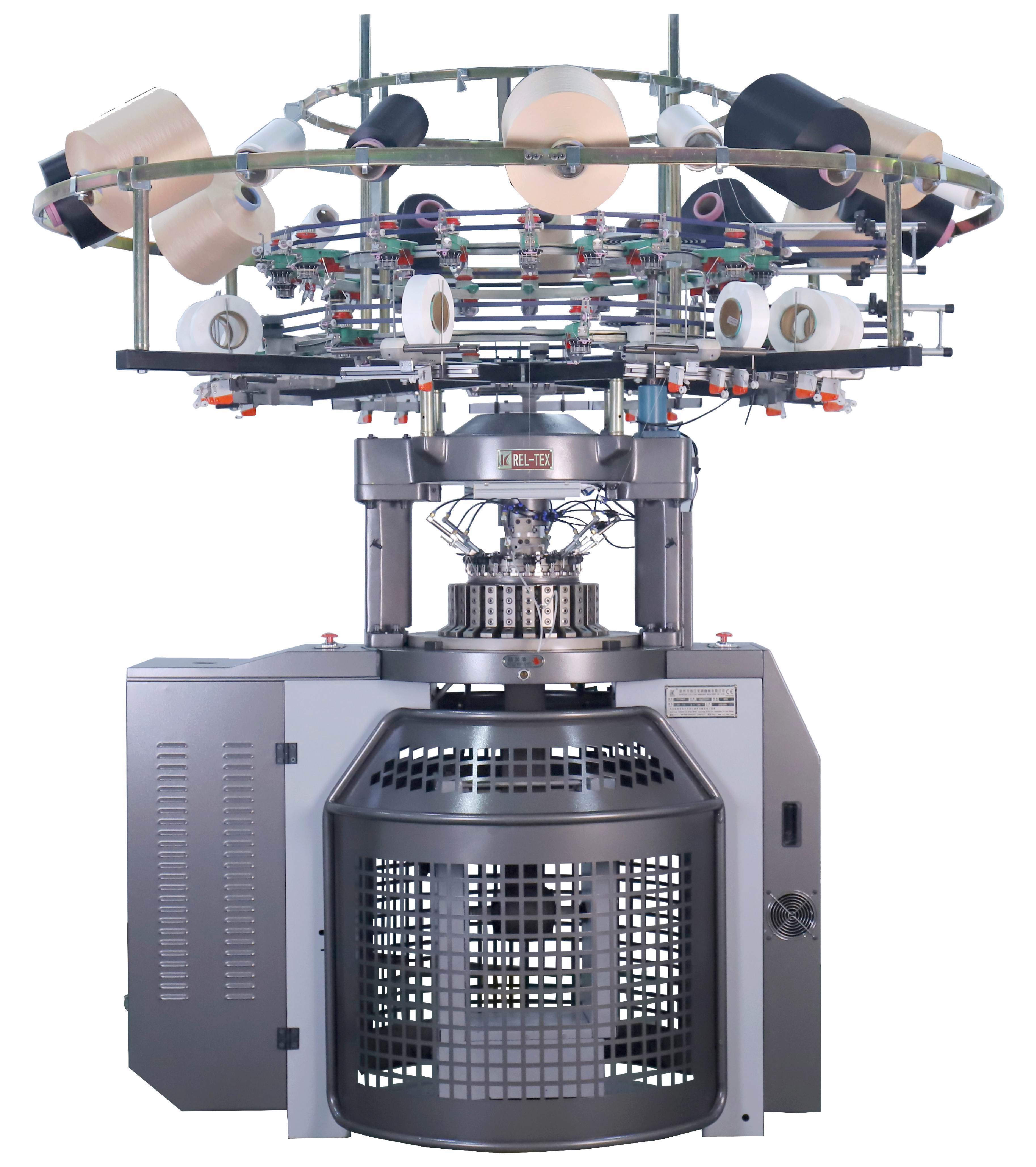

Single jersey Three Thread Fleece Circular Knitting Machine

Machine model:

YFSF

keyword:

Classification:

Product Description

This machine is equipped with 4 tracks of cams on the cylinder. The available knitting includes fish scale cloth, plain, twill and French terry. After the brushing process, it can make perfect costumes, sportswear, fleece and babies’ garments, and warm furnishing. It is very easy to change the length of loop and the structures of the fabric by adjustment of the sinker and cam.

Machine Advantage:

■Capable of meeting the requirements for high-quality plated fleece

■Offering the possibility to knit fleece variations such as pique fleece, mesh fleece, etc.

■Quickly convertible to other models like single jersey, terry, polar kniting machine by replacing the cam, needles, and sinker etc. This interchange ability can greatly benefit the cost of your investment.

Fabrics Application:

The available knitting includes fish scale cloth, plain, twill and French terry. After the brushing process, it can make perfect costumes, sportswear, fleece, baby garments, and warm furnishing.

Machine Specification:

| Model | Cylinder Dia | Gauge | Feeder |

|---|---|---|---|

| YFSF | 26"-44" | 16-24G | 3F/INCH |

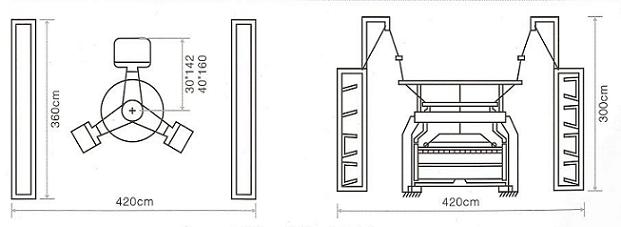

Machine Dimension:

Our plant is equipped with a lot of advanced production equipment, such as the CNC vertical lathe, high-speed milling machines, CNC machining center and so on. There devices are imported from Japan & Germany and we gradually expand our plant, now our annual output can reach more than 2000 sets, before the shipment , machines will be adjusted and inspected by our technicians, so as to make sure that all machines are qualified.

Related products