Rib (Δ 1 X 1 )

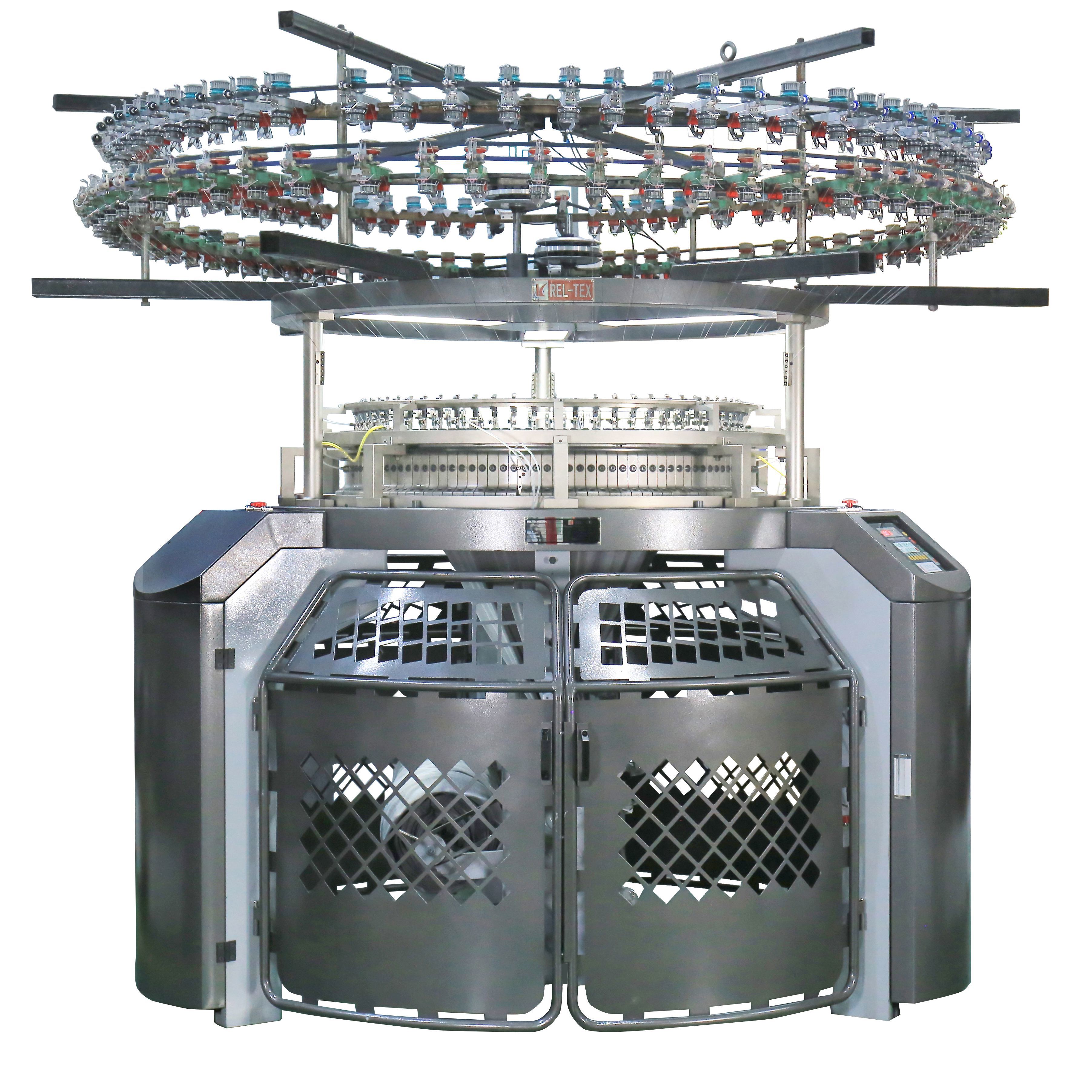

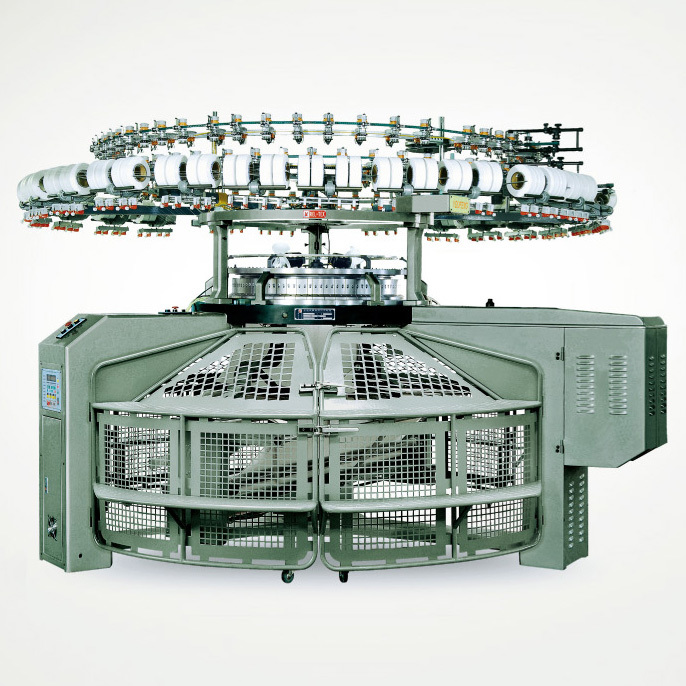

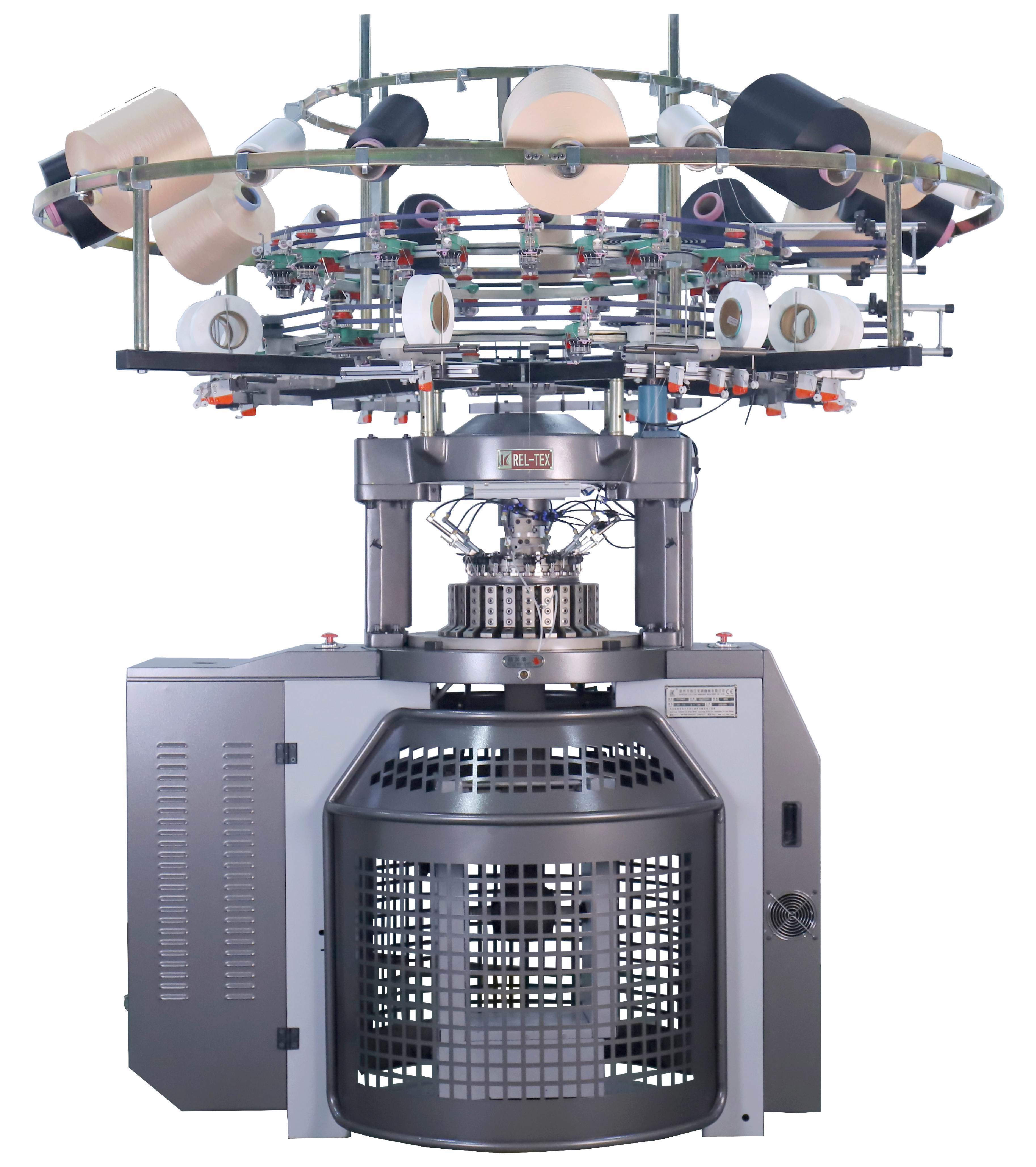

Double Jersey/Interlock/Rib Circular Knitting Machine

Machine model:

YFD/YFDJ

keyword:

Classification:

Product Description

The Double Jersey/Interlock/Rib Circular Knitting Machine possesses 2 tracks cams for the dial and 4 tracks cams for the cylinder.You can easily and rapidly change the arrangement of cams and needles to knit rib,sandwich fabric,scuba fabric,twill,interlining fabric,bourrelet,pique fabric,double jersey elastc fabric,mini jacquard fabric etc.

Product Function and Advantages:

■ Since the cams are manufactured according to some special techniques and edge of tracks has undergone a transition angle treatment,the useful life of needles and sinkers as well as the running speed of the product has been greatly increased

■ Made of high-density gray iron alloy,the cam boxes have received aging treatment for a fixed time ,so as to effectively prevent possible expansion or contraction caused by the low and high temperature during running,and to control the knitting accuracy of the machine parts.

■ Besides the frame that has received a natural aging treatment,and the interlock or rib knitting machine uses the oil immersed gear meshing drive model with good stability and slight noise.

■ Advance computer control system is applied to automatically monitor and control each operating parameter,such as regularly spraying oil in fixed quantity,dust removing ,needle breaking detection,automatic stop when the fabric is broken or it arrives the rated output,etc

Machine Specification:

Model | Cylinder Dia. | Gauge | Feeder |

|---|---|---|---|

YFD(INTERLOCK) | 3.5”-50” | 16G-40G | 84F/96F |

YFD(INTERLOCK) | 3.5”-50” | 16G-40G | 2F/2.8F/INCH |

YFDJ(RIB) | 3.5”-50” | 16G-24G | 2F/INCH |

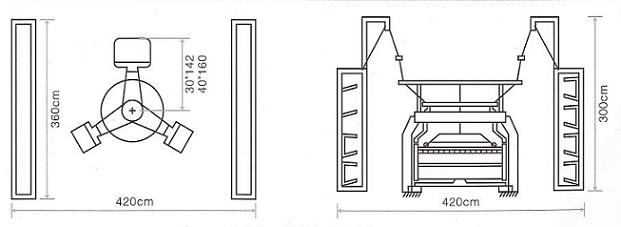

Machine Dimension:

Our plant is equipped with a lot of advanced production equipment, such as the CNC vertical lathe, high-speed milling machines, CNC machining center and so on. There devices are imported from Japan & Germany and we gradually expand our plant, now our annual output can reach more than 2000 sets, before the shipment , machines will be adjusted and inspected by our technicians, so as to make sure that all machines are qualified.

Previous

Previous

Related products